Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

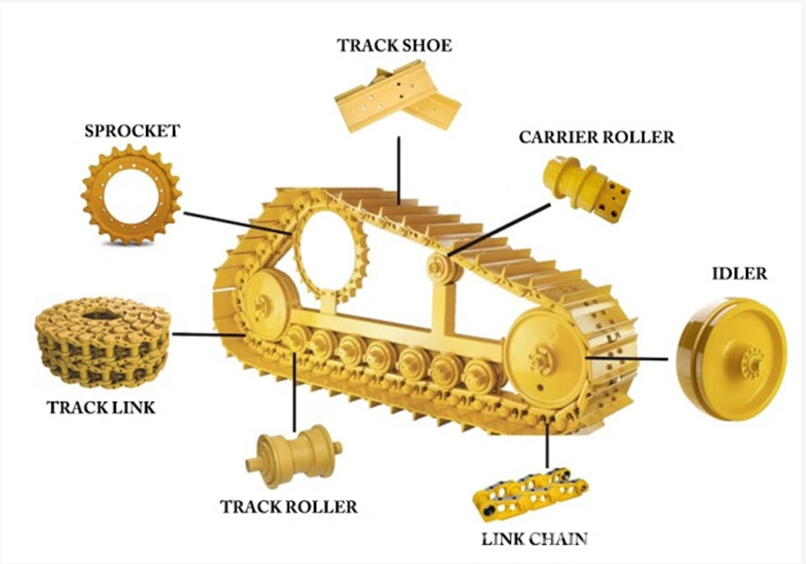

OEM/ Original Shantui/Hitachi/Komatsu Bulldozer D60/D65/D80/D85/D155/PC60/P100/PC100/PC200/PC220 Excavator Track Link

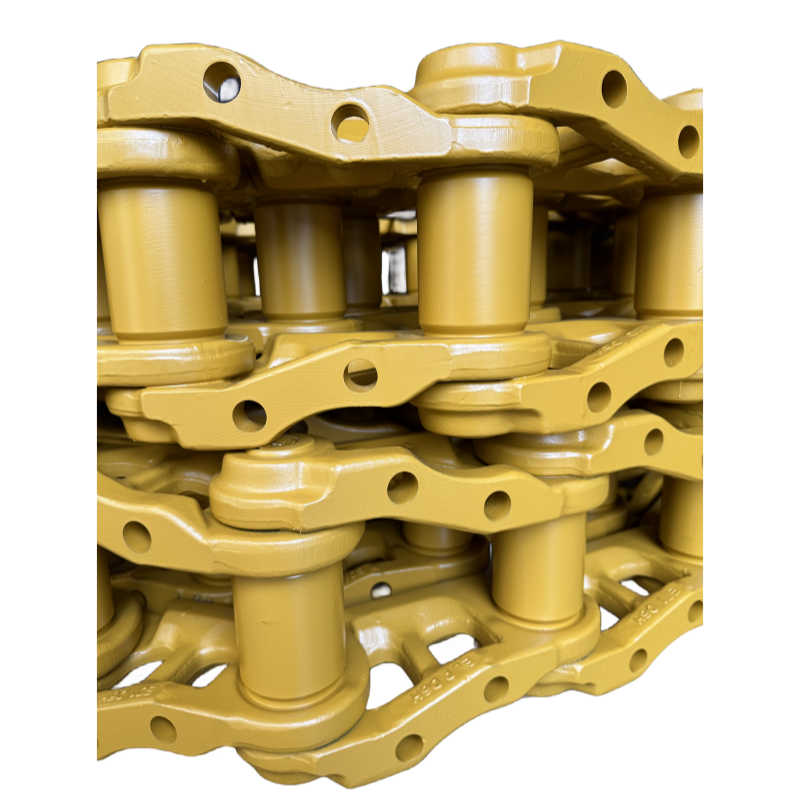

Due to oil lubrication, the service life of oil rail connecting rods is longer than traditional ones. And through our professional heat treatment, quenching and tempering, our track links have good wear resistance and impact resistance.

The quenching and tempering process ensures excellent mechanical properties, high strength, and superior wear resistance, bending resistance, and fracture resistance.

Advanced automatic machining center ensures the accuracy of assembly dimensions.

Automatic welding robots ensure that products have stable and good welding quality.

We can also produce any requested parts based on your blueprints or samples.

Excavator Track Link

track chain for excavator

We supply track chains for any type of tracked machine, from standard applications to special applications such as conveyors, bucket wheel excavators and subsea diamond dredgers.

All our chains are developed by our R&D department in cooperation with our product support specialists, who have developed extensive expertise in a wide range of applications and work closely with our customers to tirelessly test our products. Innovative materials, new geometries and special heat treatments for all components (pins, bushings and connecting rods) guarantee optimum performance and longer wear life.

- Track chain pitches from 90 mm to 350 mm link pitch – and more for cast monolithic designs.

- Dry track chains for high-performance applications, sealed and lubricated excavator track chains, lubricated chains.

- New sealed and lubricated chains for mining bulldozers.

- – Selective anti-scallop versions available.

- – Additional surface coating treatment of track pins significantly reduces pin wear.

- New integral configuration for mining excavators in the 200+ ton weight class.

- – Made of special cast steel and heat treated throughout for maximum structural life under extreme operating conditions.

- – The raceways, center teeth and pin bores of each shoe are induction hardened to optimize wear performance in the most demanding applications.

We can also produce any requested parts based on your blueprints or samples.